Resurrecting an old thread.

Last week, I managed to chip the fan blades of my ASI2600MC (while making tilt adustments, I had stuck a 2mm hex wrench accidentally into the fan opening while the fan was running :-).

You can see the chipped fan blade (at about 10 o'clock), together with some other scratches:

As expected, the camera vibrated much more than normal (a ZWO camera is never vibration free).

So, I took the opportunity (before replacing the fan) to try testing the fan isolation idea I had earlier.

https://bbs.zwoastro.com/d/16690-fan-vibration-testing-for-2600-533-and-183-cooled-cameras/6

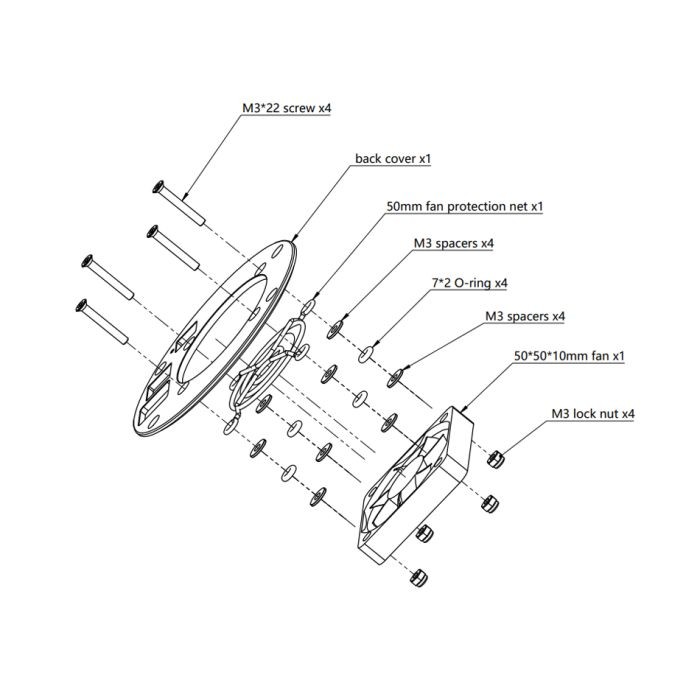

Thr o-rings kept the screw in place when mounting, so I did not install the nut next to the fan grille. And, I only used 1 oring on the right side of that drawing (although I think 2 may actually be better to ensure the lock nut does not touch the fan body).

I had reused the original M3 bolt, lock nuts and washer, and only left out ZWO's o-rings (no specs on the Duro number in ZWO's documentation, so I don't trust them).

Well, the vibration came down substantially, and even the noise appears to be completely smooth now.

Notice that this is how ZWO wants you to install their fan.

Among other poor design choices, notice that the lock nut at the end of each M3x22 screw is coupling the fan vibration directly to the body of the camera! (What happened to critical thinking classes at university, ZWO?)

I will of course replace the fan with a new one now that I have the chance to test it with a real life case (and use two o-rings at the end, instead of 1). I should have thought about purposely unbalaning the fan blades (RTV would work well for that purpose) to test vibration.

So, if you have a problem with fan vibrations from ZWO's camera, give this a try. Make sure that you buy 50A DURO o-rings. The 70A DURO ones will couple a lot of vibration through.

Chen